At Metal Central, we understand that the finishing touches on a metal roof are just as important as the roof itself. Properly installed trim not only enhances the aesthetic appeal of a roof but also ensures its longevity and performance. Here are some expert tips and tricks to help contractors achieve flawless metal roofing trim installations.

1. Accurate Measurements and Planning

Before you begin, it’s crucial to measure accurately and plan your trim installation meticulously. Start by measuring the lengths and widths of the roof sections where trim will be applied. Most trims come in standard lengths, such as 10-ft, 12-ft, or 16-ft, but custom lengths are also available. When using standard lengths, remember to account for overlaps to cover the entire length of the section. Consult the installation guide or product guides for overlap recommendations to ensure a seamless finish.

2. Understanding Trim Types and Applications

Different areas of the roof require specific types of trim. Familiarize yourself with the various trim conditions and their applications:

- Ridge Cap and Hip Ridge: Used at the peak of the roof to cover the ridge and hip lines.

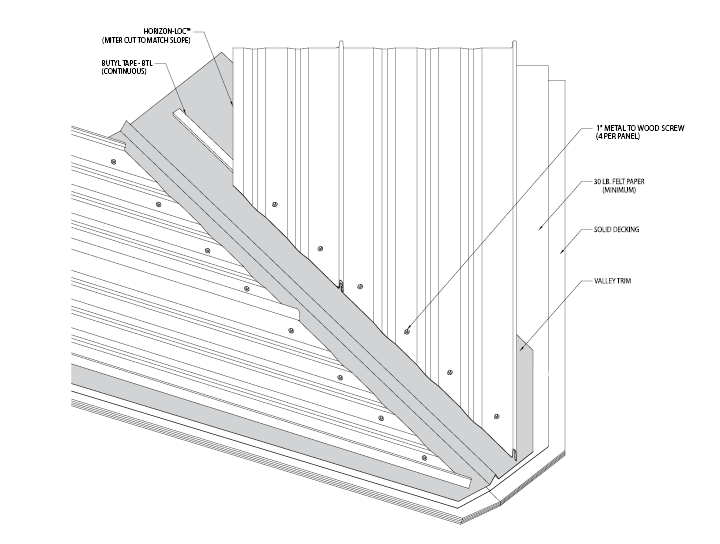

- Valley Flashing: Installed in roof valleys to direct water away from the roof.

- Eave and High Side Flashing: Applied at the roof’s edge to prevent water intrusion.

- Gable Edge and Gable Flashing: Used along the gable ends to protect against wind-driven rain.

3. Proper Angle Measurements

For trim conditions that require angle measurements, such as ridge caps, hip ridges, and valleys, ensure you measure and bend the trim accurately. This precision will help you achieve a snug fit and prevent water infiltration. Use a protractor or an angle finder to get the exact measurements needed for bending the trim.

4. Secure Installation Techniques

When installing trim, it’s essential to use the right techniques to secure it properly. Here are some key points to keep in mind:

- Fasteners: Use the recommended fasteners for your specific trim and roofing material. Ensure that fasteners are placed at the correct intervals to provide a secure hold without causing damage.

- Sealants: Apply high-quality sealants at joints and overlaps to prevent water penetration. Make sure the sealant is compatible with the metal roofing material and can withstand the local climate conditions.

5. Safety First

Safety should always be a top priority when working on a roof. Equip your team with the necessary safety gear, including harnesses, non-slip boots, and gloves. Ensure that ladders are stable and placed on flat surfaces. Avoid working on the roof during adverse weather conditions, such as rain or high winds, to minimize the risk of accidents.

6. Continuous Improvement and Training

At Metal Central, we believe in continuous improvement and staying updated with the latest industry practices. Encourage your team to participate in training sessions and workshops to enhance their skills and knowledge.

By following these tips and tricks, contractors can ensure that their metal roofing trim installations are both aesthetically pleasing and highly functional. Proper planning, accurate measurements, secure installation techniques, and a commitment to safety will help you achieve the best results for your clients. At Metal Central, we’re here to support you with high-quality products and expert guidance every step of the way.

For more information and resources, visit our FAQ page or contact your local Metal Central team. Let’s work together to deliver exceptional metal roofing solutions that stand the test of time.